The primary objective of this study is to describe the design and implementation of a mobile application (App) for tracking preparations compounded in the Pharmacy Department. Secondary objectives include: i) evaluating the time spent on resolving incidents related to the distribution of preparations before and after implementation, ii) assessing users satisfaction with the application, and iii) establishing a panel of quality indicators based on the data extracted from the App.

Methods1) Defining application requirements, identifying drugs to be included in the software and outlining different workflows. 2) Developing the App in collaboration with the supplier and integrating it with the computer programs involved in prescription and validation. Additionally, QR codes were created to identify delivery points at destination units, and suitable mobile devices were acquired. The initial phase involved user training in the application and a pilot test conducted in a hospital ward. 3) The subsequent phase focused on expansion and consolidation.

ResultsThe system includes 86.9% of all sterile preparations prepared in the Hospital Pharmacy, encompassing chemotherapy, adult parenteral nutrition, and other non-hazardous sterile preparations. Furthermore, the application has been implemented in all hospitalisation wards, day care units and two external sites. On average, 5403 preparations were tracked per month (SD = 297.3).

The time required to address incidents related to the distribution of preparations has decreased by 83% (from 38.9 to 6.6 min per day). The App regularly provides valuable management data for optimising workflow in the compounding area. Additionally, users have expressed satisfaction with the application.

DiscusionThe proposed application enables hospital staff to easily and intuitively track preparations compounded in the Pharmacy, irrespective of the computer program used for prescription. It has significantly reduced the need for manual record-keeping and has mitigated incidents associated with the distribution of sterile preparations.

El objetivo principal es describir el diseño e implementación de una aplicación para dispositivos móviles para facilitar el seguimiento de las preparaciones elaboradas en el Servicio de Farmacia Hospitalaria (SFH). Los objetivos secundarios fueron: i) evaluar el tiempo dedicado a la resolución de incidencias relacionadas con la dispensación/distribución de las preparaciones pre y post implantación de la aplicación, ii) conocer el grado de satisfacción de los usuarios, y iii) disponer de información cualitativa y cuantitativa del proceso que permita establecer indicadores de seguimiento.

MétodosSe definieron los requisitos a cumplir por el aplicativo informático, los fármacos susceptibles de entrar en el sistema y los circuitos de entrega. Se procedió al desarrollo de la aplicación por parte del proveedor e integración con los programas informáticos de prescripción/validación. Se crearon y añadieron los códigos QR de identificación en los puntos de entrega de medicamentos en las unidades de destino. Se adquirieron los dispositivos móviles necesarios. Primera etapa de formación de usuarios en la aplicación y prueba piloto en una planta de hospitalización. Posteriormente se inició la fase de expansión y consolidación.

ResultadosEl 86,9% de las preparaciones estériles elaboradas en SFH se han incorporado al sistema, incluyendo quimioterapia, nutriciones parenterales de adultos y otras preparaciones estériles no peligrosas. Se han incluido en la aplicación las salas de hospitalización, los hospitales de día y dos sedes externas. La media (SD) de preparaciones trazadas mensualmente es de 5403 (297,3).

El tiempo invertido en la resolución de incidencias relacionadas con la distribución de las preparaciones ha disminuido un 83% (de 38,9 a 6,6 minutos/día). La explotación de los datos ha permitido obtener indicadores de gestión útiles para la organización del trabajo en el área de elaboración, y los usuarios se muestran satisfechos con la aplicación.

DiscusiónLa aplicación diseñada permite realizar el seguimiento de las preparaciones de una manera intuitiva y sencilla, unificando en un solo registro preparaciones procesadas con distintos programas informáticos. Su implementación ha contribuido a disminuir considerablemente el tiempo dedicado a resolver incidencias relacionadas con la distribución de estas preparaciones.

The effective traceability of medicines during their hospital lifecycle has always been an undisputed goal of hospital pharmacy services (HPS), from receipt by the HPS to administration on wards. Article 87 of Spanish Law 29/2006, 26th July, on the Guarantees and Rational Use of Medicines and Health Products, refers to the traceability of medicines in order to ensure and reinforce their safety1. Likewise, the Guide to Good Practices for the Preparation of Medications in HPS emphasises the relevance of guaranteeing the traceability of the medication preparation process3. However, the complete traceability of the pharmacotherapeutic process remains a challenging objective due to various barriers, such as the lack of integration/interoperability of information systems or the lack of patients' electronic clinical records, among others2. Therefore, it could be said that we are facing an old problem demanding modern solutions.

Our HPS compounding area produces over 300 preparations daily, including master formulas, parenteral nutrition, cytostatics, hazardous drugs, and other individualised sterile preparations. It is essential for patient safety to ensure the accurate preparations of compounds and also that the logistics of the process functions correctly such that they are delivered in a perfect state of conservation and in the required timeframe for their administration.

Our hospital ensures the traceability of the sterile preparations process through an application that integrates component identification with barcodes and gravimetric control to guarantee accurate dosages4,5. However, manual records alone are used for monitoring the dispensing process. The multitude of preparations, destinations, and specifics of each case lead to a considerable number of incidents and complaints related to the state of the preparations, their delivery, delays, losses, and similar issues.

These incidents are a source of dissatisfaction, both for nursing staff and the HPS, due to the significant loss of time for all involved, as well as financial costs as the preparation may need to be repeated. It can also have repercussions for patients, who often experience delays in their treatment.

It has been challenging to find a single solution to these issues, given the variety of information systems that manage various forms of preparations (different software for cytostatics, parenteral nutrition, or master formulas), the complexity of the hospital itself, and the challenges involved in distributing preparations to external sites. Although we had already considered partial solutions, we decided to implement a tool that would allow all preparations to be tracked, regardless of the software used to manage their preparation.

The main objective of this study is to describe the design and implementation of an application for mobile devices (App) for tracking preparations compounded in the HPS.

Secondary objectives include assessing the time spent on resolving incidents related to the dispensing/distribution of preparations before and its implementation, evaluating user satisfaction, and establishing qualitative and quantitative data on the process in order to design monitoring metrics.

MethodsThe App was developed as part of a project that was planned in several phases:

July 2021: Defining the requirements to be met by the App, identifying the drugs most likely to be used, and outlining different workflows according to the needs and specifics of each destination. A multidisciplinary team was established for this purpose, comprising 2 pharmacists, a pharmacy technician, and a process engineer.

September to December 2021: Developing the App in collaboration with the supplier (Athenea Solutions, Spain) and integrating it with the software involved in prescription/validation (SAP, Genomi). The App was integrated with hospital applications by creating barcodes or QR codes with the essential information: preparation identification code, patient name and medical history, location, medication type and name, date of administration, and storage conditions (room temperature or refrigerated). Medication distribution points were established and labelled with a QR code for each of the destination units. The necessary mobile devices were acquired. The primary users of the App underwent training during this stage, and a pilot test was conducted in a hospital ward.

January to December 2022: Training was expanded to the rest of the users, and delivery points were added to several destination units. Since May 2022, the App's metrics, incident monitoring, and user feedback have been exported each month with the aim of improving the application.

ResultsDescription of the applicationThe current version of the application covers the preparations managed by SAP and Genomi, including cytostatics and other hazardous drugs, adult parenteral nutrition, individualised sterile preparations, and preparations for clinical trial. These preparations are distributed daily to inpatient wards, day hospitals, and external sites.

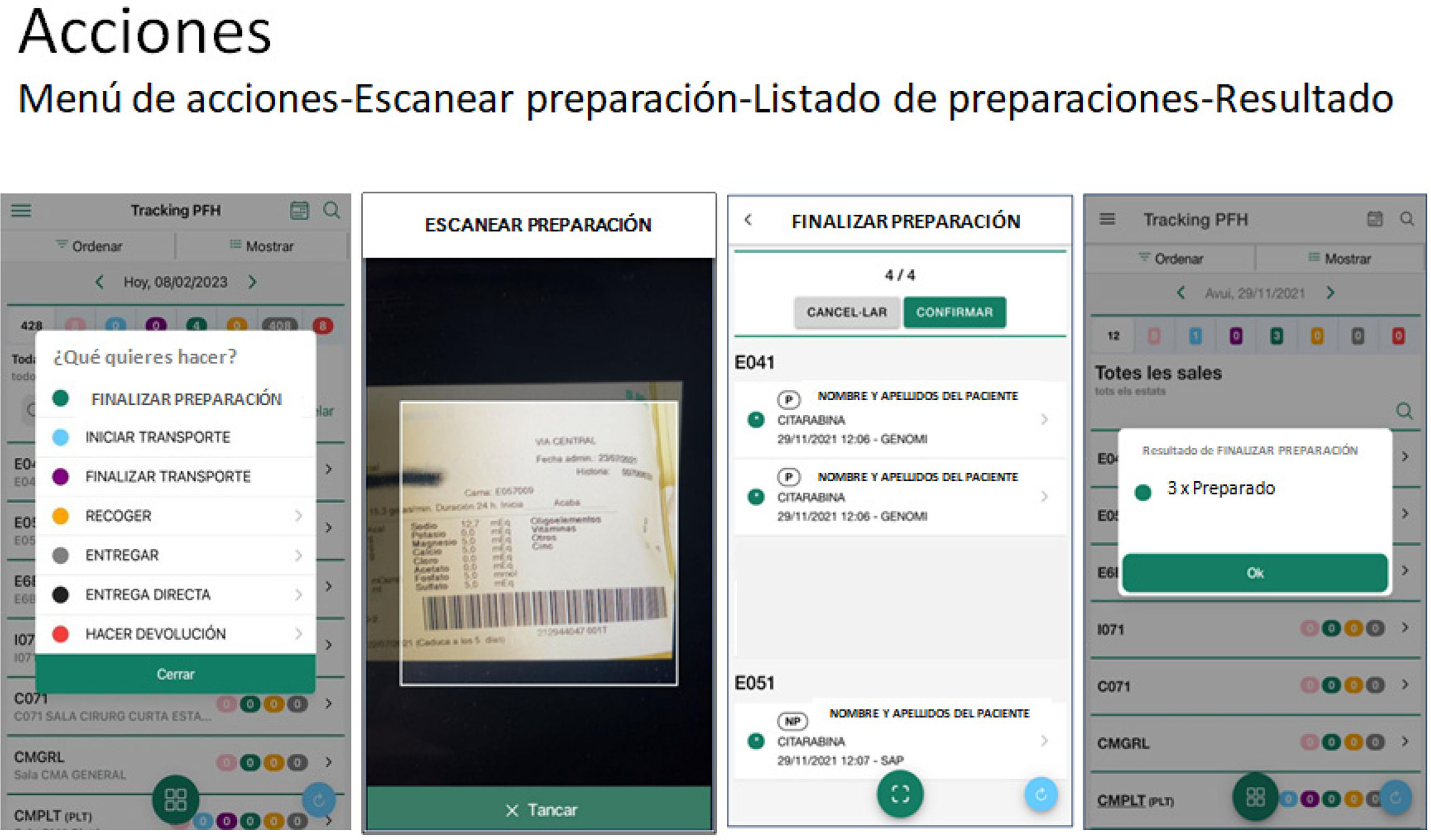

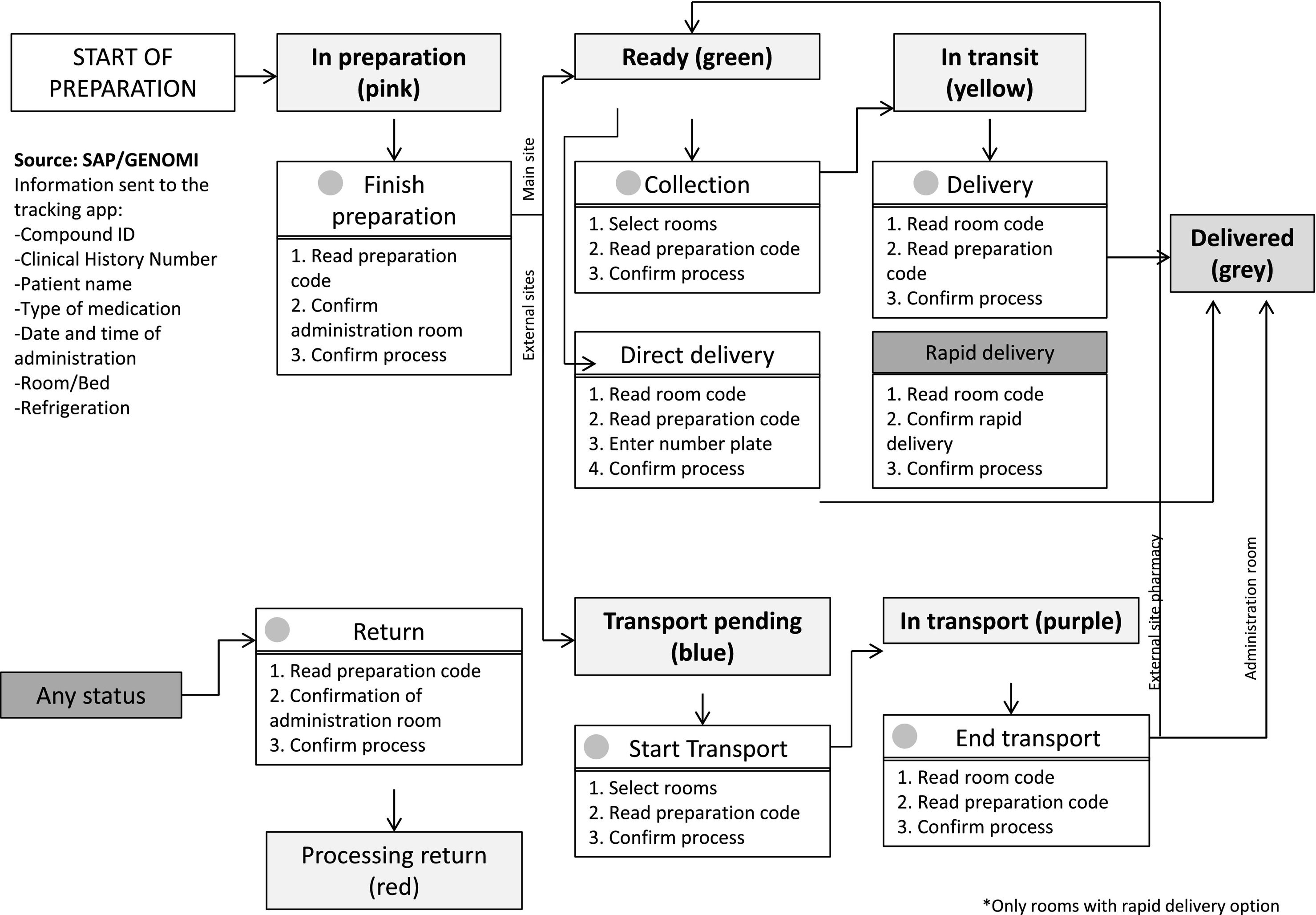

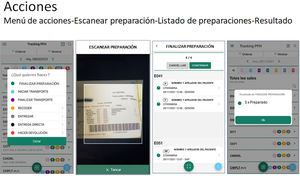

A menu displays the available actions and preparations are coded with a colour indicating their status. The preparations enter the system once they have been validated by the pharmacist, and the technician selects them as the initial step in the preparation process (status “In preparation”; colour code = pink). Once they are ready, the user selects “Finish preparation” from the action menu, scans the barcode on the label, and the preparation's status changes to “Ready” (colour code = green) (Fig. 1).

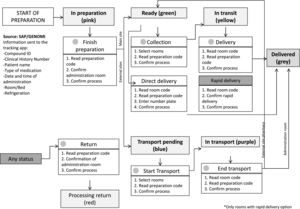

At this point, several workflows are possible, depending on the type of preparation and its destination: (Fig. 2):

Circuit 1: Distribution of the preparation by the pharmacy. The preparation is collected in the pharmacy by the orderly, who selects the “Pick up” action from the menu (colour code = yellow). The preparation is delivered to the floor in a refrigerated or room-temperature container. The delivery is checked with the QR code located at the point of delivery and then the status updates to “Delivered” (colour code = grey).

Circuit 2: Distribution of preparations to external sites. In this circuit, there are two intermediate statuses: “Start transport” (colour code = blue), which indicates delivery to the courier, and “Transport completed” (colour code = purple), which indicates that the external site has received the preparation. At the destination centre, the corresponding user checks the preparation's QR code against the delivery point QR code and the preparation's status changes to “Delivered” (colour code = grey). The identification and contact details of the courier are recorded in the system.

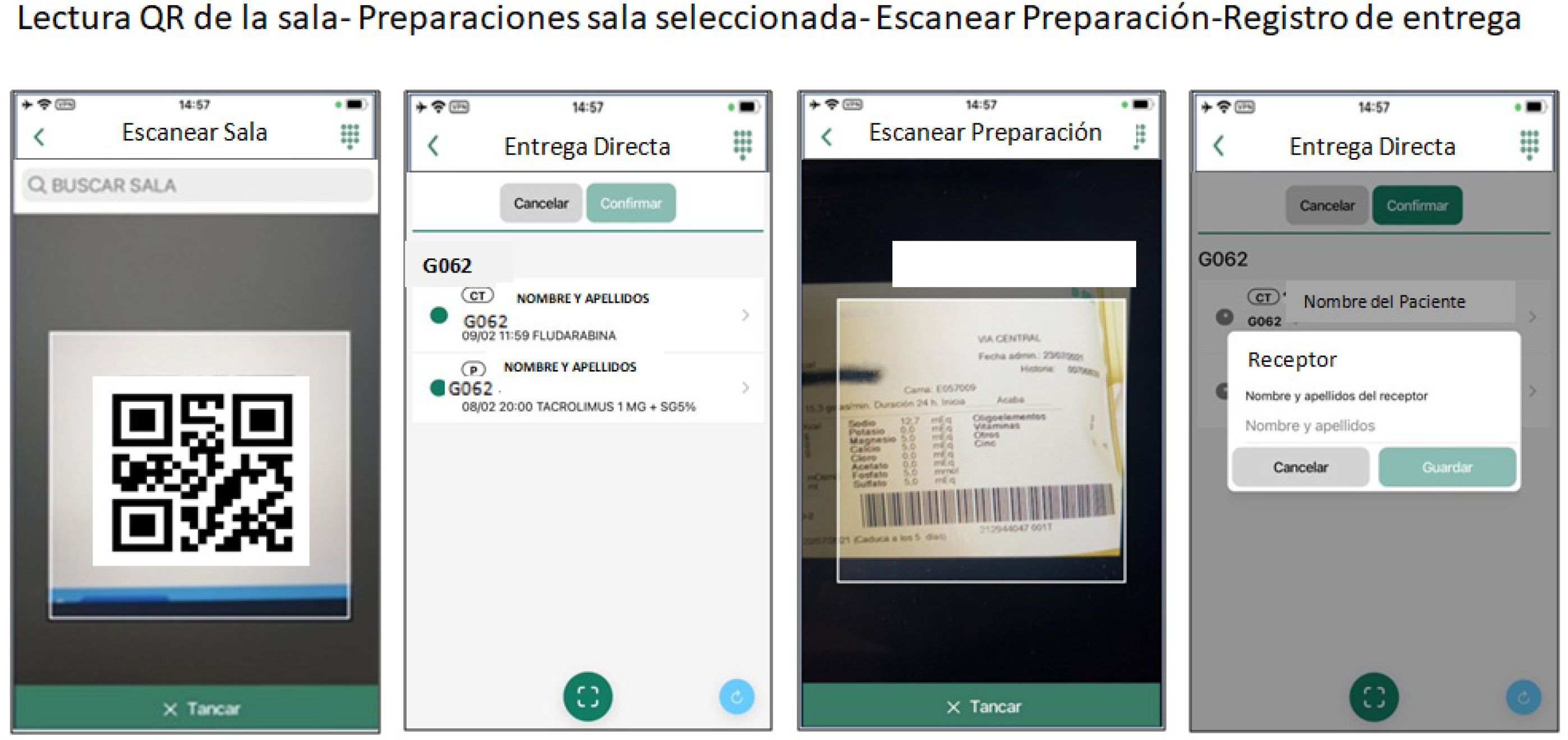

Circuit 3: Direct delivery. The pharmacy technician delivers the preparation at the counter directly to a staff member of the destination unit who comes to collect it. This is done by selecting the “Direct delivery” action (colour code = black). The App prompts the user to select the room, scan the preparation code, and the preparation changes to status “Delivered” (colour code = grey). Finally, it asks for the receiver's identification data (Fig. 3).

The “Returns” (colour code = red) option in the menu permits any preparations that could not be dispensed or administered to be returned to the pharmacy. The App prompts the user to scan the preparation and indicate the reason for the return.

The App allows searches filtered by room or by medical record number and date of administration. Users can also customise the rooms they wish to see and thus have an on-screen view of the existing preparations for the chosen day and their status. They can also see the type of preparation, the patient it is intended for, as well as the time and conditions of administration and storage. By clicking on the preparation, the user can also review its history, and see the time and date for each step of the process, as well as the individuals involved.

Although direct users access the App via their mobile phones, any authorised hospital worker with access to the App can check the status of the relevant preparations by searching via location or the patient's clinical history. Such access can be granted from any computer within the hospital's secure network by logging into the corporate website.

To date, 15 mobile terminals have been acquired. In-person training was given to all HPS users and the nursing coordinators of the hospital's units and external sites. A three-section manual has been provided to the latter such that nursing staff can train their teams and/or new personnel.

Impact on daily practiceIncidents, complaints, and time spent on solutionsA record was made of complaints related to the distribution of preparations prepared in the HPS, before and after the implementation of the App. For 9 days pre- and post-implementation, the following items were recorded: day, time, room, reason for the complaint, and time taken to resolve it.

A total of 18 complaints were recorded during the pre-implementation period (July 2021). The primary cause for complaint was misplaced preparations, constituting 77.8% (14/18) of the total. In 42.9% of these cases (6/14) the preparations were never found and had to be repeated. The HPS staff (technicians and pharmacists) spent an average of 38.9 min per day resolving complaints, amounting to more than 236 h per year.

In total, 21 complaints were recorded during the post-implementation period (July 2022). Although the number of complaints recorded was higher than in the pre-implementation period, it should be noted that most of these questions addressed the availability of the preparation (status green), which can be easily solved by consulting the App. It is likely that the introduction of the new consultation system increased the number of calls because the users were not yet familiar with the App's functions. In contrast, a significant decrease was observed in the loss of preparations: of the total number of complaints, only 3 (14.2%) were due to loss, and of these, only one had to be repeated. During this period, the average daily time spent on resolving claims was reduced to 6.6 min per day, or 40 h per year.

Thus, there was an 83% decrease in the time dedicated to resolving complaints. It should also be noted that, in addition to the time saved for caregiving, this decrease represents a significant improvement in both the quality of care and in relations between the services and staff because of the reductions in complaints and other issues.

Information on the process. Creation of follow-up metricsCurrently, a monthly data extraction process is conducted, enabling data to be retrieved on the preparations compounded and dispensed. We have also been able to objectify/quantify details of the process, thus allowing a more rational distribution of resources, predictions of daily activity, and the identification of improvement opportunities.

Some of the metrics we have created include the following aspects:

- •

Number of preparations, sorted by type of medication and their distribution according to the day of the week. This enables anticipating on which days of the week workload will be higher and to organise the area appropriately.

- •

Scheduling of preparations. This allows us to see which time slots are the most problematic and those in which we could potentially increase the number of preparations, if necessary. This information can help optimise workflow in the compounding area.

- •

The mean time between a preparation being ready for processing and it being finalised.

- •

The mean time between a preparation being finalised and it being delivered to the final location.

- •

In the case of chemotherapy, the number of treatments that are prepared the day before administration and the number that are prepared and administered on the same day.

- •

Number of preparations delivered later than the scheduled administration time.

- •

Number of returns: the number of unused preparations that are returned to the HPS is a relevant metric, as their shelf life often allows for their reuse. In addition, an increase in this metric for no known reason may be indicative of poor management.

To date, the application has covered all 33 inpatient wards, 15 day hospitals, the clinical trials unit, and the 2 external sites. From May to December 2022, 43,220 preparations have been traced (86.9% of the total number of preparations compounded), with a monthly average of 4158 cytostatics, 792 parenteral nutritions, and 452 individualised sterile preparations.

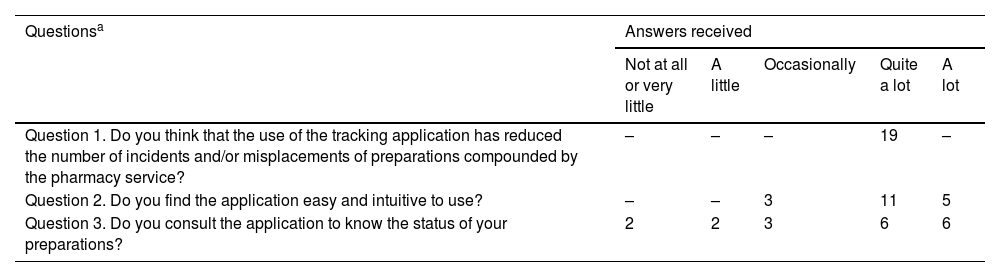

User satisfactionAfter 4 months of operation, a satisfaction survey was conducted among a sample of 35 users directly involved in the process, comprising pharmacists, pharmacy technicians, nurses, assistants, and orderlies. Nineteen responses were received (54.3%). The survey consisted of 3 single-response queries (Table 1) and 3 open questions asking respondents to provide feedback on a positive or strong aspect, on a negative aspect, and a suggestion for improvement.

Satisfaction survey.

| Questionsa | Answers received | ||||

|---|---|---|---|---|---|

| Not at all or very little | A little | Occasionally | Quite a lot | A lot | |

| Question 1. Do you think that the use of the tracking application has reduced the number of incidents and/or misplacements of preparations compounded by the pharmacy service? | – | – | – | 19 | – |

| Question 2. Do you find the application easy and intuitive to use? | – | – | 3 | 11 | 5 |

| Question 3. Do you consult the application to know the status of your preparations? | 2 | 2 | 3 | 6 | 6 |

Most of the responses on the positive aspects agreed that it is highly advantageous to be able to check the status of a preparation from any location and in real time. Furthermore, the number of complaints has fallen since the application was implemented. As for negative aspects, responses indicated that not all preparations are traced and also drew attention to the frequency with which the password needs to be entered, given that each time the screen is locked, the password must be re-entered for security purposes.

Users also suggested a number of improvements: the traceability system should extend past the delivery time and include the administration of the drug to the patient; more mobile terminals should be provided; and the search engine should be improved. The latter improvement should not only allow searching by room and clinical history number, but also filtering by drug or type of preparation, by date of administration, or even by multiple fields simultaneously.

DiscussionThis study describes the design and implementation of a mobile application (App) for tracking preparations compounded in the Hospital Pharmacy Service (HPS).

Since the App was launched in April 2022, there has been a reduction in the time taken to resolve complaints and the need for repeat preparations caused by misplacement. Manual records have been progressively eliminated and are negligible at this point in time.

The data collected by the App makes possible the detailed monitoring of preparation, transportation, delivery, and administration schedules. This information and its analysis has provided key metrics for managing the compounding area and optimising workflow.

It should be borne in mind that in order to successfully implement an innovative technology that functions effectively, an environment must be created in which everyone feels fully involved and understands the potential benefits of the new technology. The active involvement of the entire interdisciplinary team is and remains crucial, as does close attention to the all user opinions and perspectives regarding the App. In this project, a continuous improvement cycle has been established, based on the experiences and opinions of the users, who are generally satisfied with the application and consider that the benefits far outweigh the time invested in reading the codes.

To date, one of the main limitations is that the App does not yet include all the preparations compounded in the HPS. It is currently limited to cytostatics, hazardous drugs, individualised sterile preparations, and adult parenteral nutrition. Paediatric master formulas and parenteral nutrition remain part of the manual workflow, pending integration with the App. Nonetheless, digitally traced preparations comprise 86.9% of the total.

The last tracked status that appears on the current version of the App is “Delivery to the final destination points”. Work is currently in progress to include another stage—“Administration to the patient”—by matching the patient's wristband code with the preparation label code. This will provide traceability from preparation to administration and enhance patient safety. The use of mobile devices to read codes is an advantage due to their ease of use and intuitiveness. However, their use requires a sufficient number of terminals, which can be a limitation in some cases. When the mobiles are shared, each time the screen is locked, the password must be re-entered for security purposes.

Recent years have witnessed a rise in the use of mobile apps directed toward enhancing patients' clinical care6–8. Traceability in healthcare also requires the use of innovative technologies for the effective monitoring of the pharmacotherapeutic process. The current App is an example of such innovation: preparations can be tracked in an intuitive and simple way, and preparations processed with different computer programs can be fully integrated in a single record.

We believe that this application can be useful in other centres seeking solutions to two common problems in Spanish hospitals: the traceability of compounded preparations; and the existence of multiple computer programs for processing preparations.

Ethical responsibilitiesAs this study does not include patient data, it therefore does not require the approval of the hospital's Ethics Committee. All authors have fulfilled their ethical responsibilities.

This project was awarded at the sixth SEFH/ROVI Awards for the Development of Hospital Pharmacy in 2022. The prize was presented at the 67th National Congress of the Spanish Society of Hospital Pharmacy on 26 November 2022 in Barcelona. Likewise, the study “A mobile application for monitoring preparations compounded in a Pharmacy Department” (Seguimiento de las preparaciones elaboradas en el servicio de farmacia a través de una aplicación para dispositivos móviles), which was based on this application, was presented at the same conference and received the prize for the best scientific communication by technical engineers.

FundingThis project was not funded by any body external to the hospital.

AuthorshipCarmen López-Cabezas contributed to the conception and design of the project, data analysis and interpretation, writing the article, and approval of the final version.

Ana María Marín Romero contributed to the conception and design of the project, its development and implementation, data collection, analysis, and interpretation, writing the article, and approval of the final version.

Silvia González Suárez contributed to the development and implementation of the project, data collection, analysis, and interpretation, writing the article, and approval of the final version.

Dolores Soy Muner contributed to the conception and design of the project, critical revision, and approval of the final version.

Guadalupe Ballesteros Cabañas, Rodolfo Juncos Pereira, Carolina Lesta Domene, and Yolanda Rial Domínguez contributed to the development of the project, its implementation, and data collection for publication.

Contribution to the scientific literatureThe traceability of medications during their hospital lifecycle has always been a goal of pharmacy services. However, the complete traceability of the pharmacotherapeutic process from preparation to administration remains a challenge. This project presents an innovative solution that could be useful in other centres seeking to improve these processes in a straightforward and intuitive way.

Its implementation in our centre has had a positive impact on daily practice. It has contributed to a decrease in the time spent on resolving incidents related to the distribution of preparations. Furthermore, it has allowed us to obtain key metrics on daily preparation area workflow and identify opportunities for improvement.

We wish to express our gratitude to Lluís Mañes, a process engineer and project coordinator at our hospital, and Ignasi Nicolás from Athenea Solutions, who developed the software application.